Product Description

1.Can you provide sample free?

Yes ,we can provide free samples with in 0.5kg.

2.What kind of payment terms you can accept?

We can accept T/T,L/C, Western Union and Paypal.

3.What about your steel ball’s quality?

Checking in the whole manufacturing process &100% inspection before shipment ensure the quality of our products.

4.What’s your packing method?

A) Inner packing: Dry packing or oil packing are provided according to you needs.

B) Outer packing:

1)volatile rust preventive paper + poly bag + iron drum + wooden / iron pallet.

2)25kg poly bag + carton + wooden pallet or wooden box.

3)customized packing.

5.What’s your delivery time?

Within 3-30 days according to your required size and quantity.

6.Is your steel ball competitive?

Yes, We are steel ball manufacture more than 30+ years.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, IATF16949 |

| Standard Parts: | Yes |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample sliver

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you determine when a screw ball needs to be replaced?

Determining when a screw ball, also known as a ball screw, needs to be replaced requires careful assessment of its condition and performance. Several factors should be considered to determine if replacement is necessary. Here are some key indicators to help determine when a screw ball needs to be replaced:

- Excessive Wear: If the screw ball has undergone significant wear, such as worn ball bearings, damaged raceway, or excessive backlash, it may be an indication that replacement is necessary. Visual inspection and measurements of critical dimensions can help assess the extent of wear and determine if it has reached a point where replacement is warranted.

- Reduced Performance: A noticeable decline in the performance of the screw ball assembly, such as decreased positioning accuracy, repeatability, or load-carrying capacity, can indicate the need for replacement. If the system is no longer meeting the required specifications or is unable to perform its intended function reliably, replacement should be considered.

- Severe Damage: If the screw ball has suffered severe damage, such as fractures, deformations, or extensive pitting and corrosion, it is likely beyond repair and should be replaced. Severe damage can compromise the structural integrity and functionality of the assembly, leading to safety risks and unreliable operation.

- Frequent Failures: If the screw ball assembly is experiencing frequent failures or breakdowns, even after repairs or maintenance efforts, it may indicate that the wear and tear have reached a critical point. Frequent failures can result in costly downtime, reduced productivity, and increased maintenance costs. In such cases, replacing the screw ball assembly can be a more cost-effective solution in the long run.

- Unrepairable Issues: Certain issues with the screw ball assembly may be unrepairable or uneconomical to fix. For example, if the assembly has been subjected to severe contamination or exposure to corrosive substances that have caused irreversible damage, replacement may be the only viable option. Similarly, if critical components or specialized parts are no longer available or obsolete, replacement may be necessary.

- Manufacturer’s Recommendations: It is important to consult the manufacturer’s recommendations and guidelines regarding the expected lifespan and replacement intervals for the specific screw ball product. Manufacturers often provide guidelines on the maximum allowable wear, recommended maintenance practices, and replacement criteria. Adhering to these recommendations can help ensure safe and reliable operation.

It is crucial to thoroughly assess the condition of the screw ball assembly and consider the impact of its performance on the overall system. Regular inspection, maintenance, and monitoring can help identify signs of wear, damage, or decline in performance. If any of the above indicators are present, consulting with experts or the manufacturer can provide valuable insights and guidance on whether replacement is necessary.

When replacing a screw ball, it is important to select a suitable replacement that meets the application requirements, including load capacity, accuracy, speed, and environmental considerations. Proper installation, lubrication, and maintenance of the new screw ball assembly are also essential to ensure optimal performance and longevity.

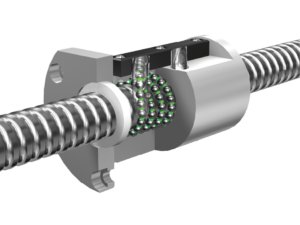

How do screw balls differ in design from traditional screws?

Screw balls, also known as ball screws, differ in design from traditional screws in several key aspects. While both serve the purpose of converting rotational motion into linear motion, screw balls are specifically engineered to provide higher efficiency, precision, and load-carrying capacity. Here are the main design differences between screw balls and traditional screws:

- Thread Configuration: Traditional screws typically feature a continuous helical thread that extends along the entire length of the screw. In contrast, screw balls have a specialized thread configuration that combines helical threads with a groove or raceway along the screw shaft. This raceway contains a series of recirculating ball bearings, which act as rolling elements between the screw shaft and the ball nut.

- Ball Bearings: The presence of ball bearings is a fundamental distinction between screw balls and traditional screws. Ball bearings in screw balls enable smooth rolling motion between the screw shaft and the ball nut, reducing friction and improving efficiency. The ball bearings also distribute the load evenly along the length of the screw, allowing for higher load-carrying capabilities compared to traditional screws.

- Accuracy and Precision: Screw balls are designed to provide high levels of accuracy and precision in linear motion applications. The presence of ball bearings minimizes axial play and backlash, resulting in improved positional accuracy and repeatability. Traditional screws, on the other hand, may have more play and can introduce greater variability in motion due to the sliding friction between the screw threads and nut.

- Efficiency: Screw balls are engineered for high efficiency in converting rotational motion into linear motion. The rolling contact between the ball bearings and the raceway reduces frictional losses, resulting in improved power transmission and energy efficiency. Traditional screws, with their sliding contact between the screw threads and nut, tend to have higher frictional losses, leading to lower overall efficiency.

- Load-Carrying Capacity: Screw balls are designed to handle higher loads compared to traditional screws. The presence of ball bearings distributes the load evenly along the screw shaft, reducing localized stress concentrations. This allows for increased load-carrying capacity and improved rigidity, making screw balls suitable for applications requiring higher thrust or axial load capabilities.

- Backlash and Reversibility: Screw balls exhibit lower backlash compared to traditional screws. Backlash refers to the amount of free motion or play between the screw and the nut when changing direction. The presence of ball bearings in screw balls minimizes the backlash, enhancing system responsiveness and accuracy. Traditional screws may have more noticeable backlash due to the sliding contact between the screw threads and nut.

These design differences make screw balls well-suited for applications that demand high precision, efficiency, and load-carrying capabilities in linear motion systems. They are commonly used in various industries, including robotics, CNC machinery, aerospace, and automotive, where accurate and reliable linear motion is essential.

When selecting between screw balls and traditional screws for a specific application, it is crucial to consider the design requirements, load capacity, accuracy needs, and environmental conditions. Consulting the manufacturer’s documentation, technical specifications, or seeking professional advice can help in choosing the most appropriate solution for a given application.

How do you select the right size of a screw ball for a specific application?

Selecting the right size of a screw ball, or screw, for a specific application involves considering several factors that influence the functionality and performance of the screw. Here are some key considerations when determining the appropriate size:

- Thread Type: The first step in selecting the right screw size is to determine the thread type required for the application. Common thread types include machine screw threads, wood screw threads, self-tapping screw threads, and sheet metal screw threads. Each thread type has specific dimensions and characteristics that influence the choice of screw size.

- Diameter: The diameter of the screw is a critical factor in determining its size. It is typically measured as the major diameter, which is the outside diameter of the threaded portion of the screw. The diameter should match the size of the hole or the material being fastened. Using a screw with the correct diameter ensures proper thread engagement and adequate holding strength.

- Length: The length of the screw is determined by the thickness of the materials being joined. The screw should be long enough to penetrate through the first material and provide sufficient engagement in the second material to create a secure connection. It is important to consider the total thickness of the materials and any additional components, such as washers or spacers, when determining the appropriate screw length.

- Head Type: The head type of the screw should also be considered for specific applications. Common head types include flat head, pan head, round head, and countersunk head. The choice of head type depends on aesthetic preferences, flushness requirements, and the type of tool used for installation.

- Material: The material of the screw should be selected based on the application’s environmental conditions and the materials being fastened. Different materials offer varying levels of corrosion resistance, strength, and compatibility with specific materials. Common screw materials include stainless steel, carbon steel, brass, and aluminum.

- Load and Application: Consider the anticipated load and the specific application requirements. If the screw will be subjected to heavy loads or vibrations, it may be necessary to choose a larger size or a screw with additional features like locking threads or increased tensile strength.

When selecting the right size of a screw ball, it is essential to consult the manufacturer’s specifications, guidelines, or engineering resources specific to the application. These resources often provide detailed information on recommended screw sizes based on the intended use, material compatibility, and load requirements.

It is also advisable to consult with professionals, such as engineers or experienced tradespeople, who have expertise in the specific application or industry. They can provide valuable insights and recommendations based on their experience and knowledge of best practices.

By considering factors such as thread type, diameter, length, head type, material, load, and application requirements, the appropriate size of a screw ball can be selected to ensure optimal performance, durability, and reliability in a specific application.

editor by CX 2024-03-29

Leave a Reply